The Rise of Industry Cloud Platforms

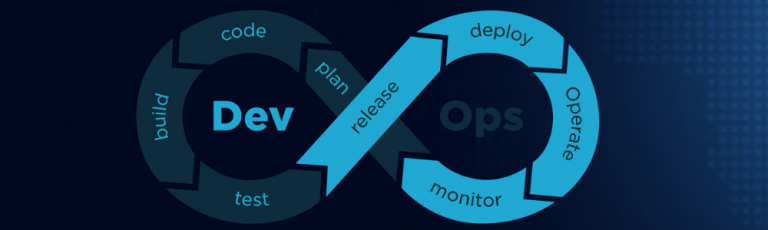

The Rise of Industry Cloud Platforms ATMECS Content Team 3 Minutes Read Posted on July 18th, 2024 Introduction Traditional cloud providers like AWS, Azure, and Google Cloud Platform (GCP) offer a vast array of services. While powerful, these platforms cater to a broad range of needs. Industry cloud platforms, on the other hand, are specialized solutions designed to address the unique requirements of specific industries. Here’s what sets them apart: Pre-built Tools and Compliance: Industry cloud platforms come pre-loaded with industry-specific tools, templates, and workflows. This eliminates the need for extensive customization, saving businesses time and resources. Additionally, these platforms are built with compliance in mind, ensuring adherence to regulations specific to your industry (e.g., HIPAA in healthcare, GDPR in data privacy). Enhanced Security and Performance: Industry cloud platforms often leverage the security expertise of the cloud provider and industry leaders, offering robust security features tailored to industry threats. Additionally, these platforms are optimized for specific workloads, leading to improved performance and reliability. Faster Innovation and Time to Market: Industry cloud platforms provide pre-configured solutions that streamline development and deployment. This allows businesses to focus on innovation and get their products or services to market faster The Emerging Value of Industry Cloud Platforms The value proposition of industry cloud platforms extends beyond just offering industry-specific tools. Here are some emerging trends that highlight their growing importance: Deeper Industry Insights: Industry cloud providers are increasingly partnering with domain experts to embed industry best practices and data models into their platforms. This offers businesses access to valuable industry-specific insights that can optimize operations and decision-making. Ecosystem Enablement: Industry cloud platforms are fostering the creation of vibrant ecosystems. These ecosystems connect businesses with industry-specific partners, software solutions, and data sources, further accelerating innovation and collaboration. Focus on Industry-Specific Use Cases: Industry cloud platforms are continuously evolving to address industry-specific use cases. This could include anything from real-time analytics in manufacturing to secure patient data management in healthcare. Benefits of Industry Cloud Platforms for Your Business Reduced Costs and Improved Efficiency:Industry cloud platforms eliminate the need for expensive upfront hardware investments and simplify IT management. Additionally, pre-built tools and optimized workflows can significantly enhance operational efficiency. Enhanced Security and Compliance:As mentioned earlier, industry cloud platforms prioritize security features specific to your industry and ensure regulatory compliance. Faster Innovation and Scalability:The agility and pre-built features of industry cloud platforms enable businesses to experiment, iterate, and scale their solutions rapidly. How ATMECS Can Help You Navigate the Industry Cloud At ATMECS, we understand the complexities of digital transformation and the power of industry cloud platforms. We offer a comprehensive suite of services to help your business leverage the benefits of this evolving technology: Industry Expertise: Our team possesses in-depth knowledge of various industries and their specific cloud needs. Cloud Strategy and Migration: We help you develop a customized cloud strategy and guide you through the migration process to ensure a smooth transition. Application Development and Modernization: Our team can develop new cloud-native applications or modernize existing ones to leverage the full potential of industry cloud platforms. Managed Services and Support: We offer ongoing support and maintenance to ensure your cloud environment is secure, optimized, and running smoothly. The Future is Specialized: A Tailored Cloud for Every Industry The cloud revolutionized how businesses operate, but a one-size-fits-all approach can’t address the unique needs of every industry. Industry cloud platforms are the answer, offering a future where the cloud is as specialized as the problems it solves. A Transformation Beyond Efficiency: While traditional cloud providers deliver scalability and agility, industry cloud platforms go a step further. They transform the cloud into a strategic asset, deeply integrated with the specific workflows, regulations, and data models of your industry. Imagine a healthcare provider leveraging an industry cloud platform to securely manage patient data, streamline billing processes, and collaborate with specialists in real-time. Now, picture a manufacturer using an industry cloud platform to optimize production lines, predict equipment failures, and gain real-time insights into supply chains. These are just a few glimpses into the specialized future of cloud computing. Industry cloud platforms will not only enhance efficiency, but also: Fuel Industry Innovation: With pre-built tools and industry-specific data models, businesses can experiment faster and develop innovative solutions tailored to their market. Break Down Data Silos: Industry cloud platforms can connect businesses with industry-specific data sources and partners, fostering collaboration and unlocking valuable insights. Simplify Regulatory Compliance: Built-in compliance features and adherence to industry regulations will help businesses navigate the complexities of data privacy and security. Conclusion The traditional cloud landscape is fragmenting, giving rise to a powerful new era of industry-specific platforms. As these platforms mature, they’ll offer not just industry-tailored tools, but also deep industry insights, vibrant ecosystems, and solutions for specific use cases. The future of cloud computing is undoubtedly specialized. By partnering with ATMECS, a leader in digital engineering services, you can navigate this exciting shift and leverage the immense potential of industry cloud platforms.

The Rise of Industry Cloud Platforms Read More »